معلومات عنا

🚀 Print at the Speed of Imagination!

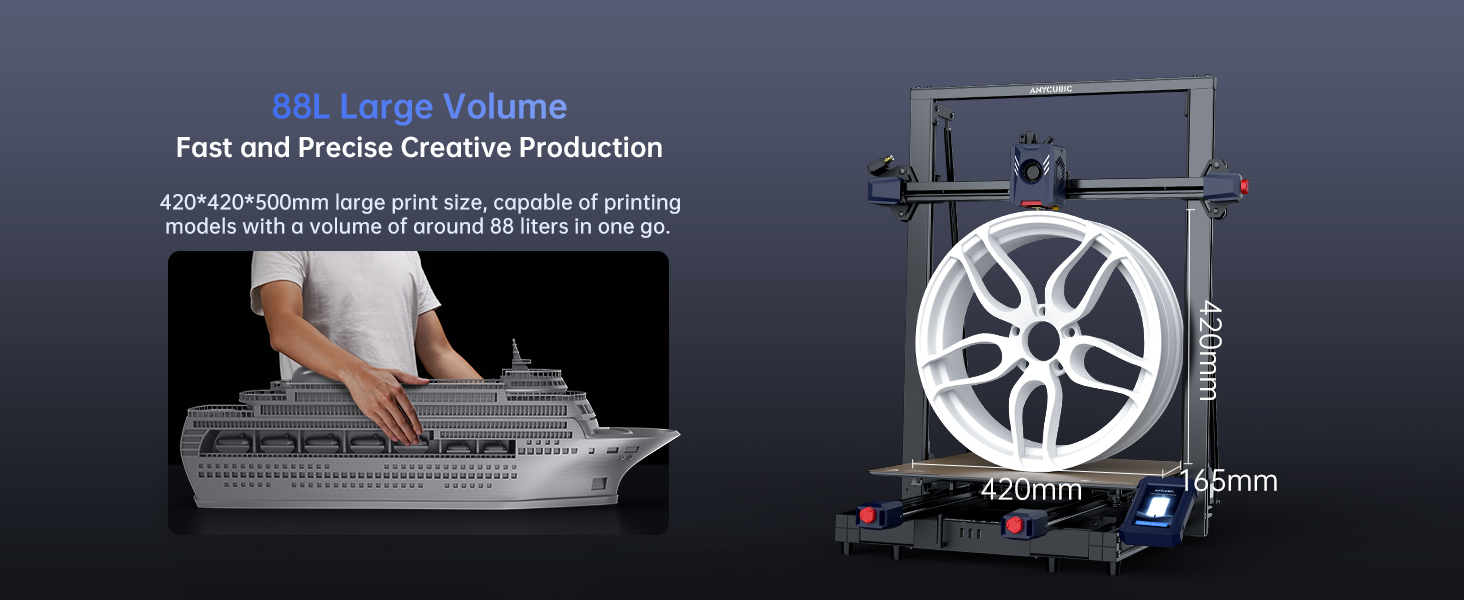

The Anycubic Kobra 2 Max 3D Printer is a high-performance machine designed for professionals, featuring a maximum printing speed of 500mm/s, a large printing volume of 420x420x500mm (88L), and advanced auto-leveling technology. It ensures high-quality prints with enhanced detail and stability, making it an ideal choice for prototyping and custom designs. With robust customer support and a commitment to quality, this printer is built to elevate your creative projects.

T**S

Great value!

This is a beast, easy to use and configure and get spare parts for it. After use I did end up getting an insulated put-together box for it to regulate the heat better on larger parts. This can print large projects well like a B1 Droid chest or helmets with ease.

T**C

Poor quality components but works well when it works.

When it works, it's great. I appreciate the large format capabilities, and the prints that actually completed turned out pretty good (after the expected tuning).Unfortunately, there have been quite a few problems with this printer. Out of the box, the axis sensors had poor quality connectors. I had to splice a new connector into the Y axis right out of the gate. X axis limit switch worked intermittently as well but seems to have resolved itself. Very very very cheap and poor quality components.I have had this for about 3 weeks and already needed to replace the thermistor in the hot end (tbh it was easier just to buy a whole new head, luckly cheap). But the worst is now the bed doesn't stay at temp as soon as printing starts. It will heat/preheat fine then just shut off. No GCode or slicer issues (previously succesfful prints now fail), and clearly the heater element is working. Ambient temps are about 20*C and no drafts, no fan usage (PETG @255/80).So -- you get what you pay for. Seems like many folks on here have been lucky but I've had more downtime than uptime with multiple independent failures. Being cheap, at least its been cheap to repair but can't say it has been convenient or positive.

C**N

Not as easy as my other Anycubic printers, but tech support was amazing!

I mostly use my printers for TTRPG terrain using PLA filament. At first I was disappointed and a bit overwhelmed once I realized that the bed wasn't level and my prints were failing. Tech support was AMAZING in helping me troubleshoot the situation and pointing me in the right direction as to how to fix my situation.After watching a video provided by tech support, I was able to resolve my issue, and help the auto leveling process along (I know, I know, it should be auto leveled by default, but sometimes this just isn't the case). After all the issues I had when I first started out trying to level an Ender 3, the solution provided was simple, to the point, and I saw immediate results.Another review gave suggested parameters to change to ensure quality prints and they were spot on. If you're running on the "Standard" speed, it's really fast, but the acceleration speed and jerk CAN lead to less than stellar prints. Adjusting these settings in accordance to the snip I took from the review that helped me can be seen above. Once it's dialed in, you won't be disappointed!At the "Stable" speed setting, I was able to finish the dragon skull print in just over 9 hours and the rubble scatter terrain in around 3. Compared to my Anycubic Vyper, I'm shaving off literal days of printing time for each print.

J**N

Upgradable to absolute GEM! (But broken by default, HANGS!)

**Assembly**Got this a few days ago. Assembly was smooth, but check the (short) video on YouTube, rather than rely solely on the booklet.The video of the assembly makes it much more clear, but overall, no issues. **Hang Issue (Firmware!)**After a simple benchy, the first print STOPPED MID PRINT, with the fan still blowing, and screen blank and unresponsive. This happened on the second try, and kept happening on various prints. LAME!However, the interwebs eventually solved the issue for me, and others here have said it as well:!!! You must UPDATE THE FIRMWARE for the printer to work !!!This is super easy, you just connect to Wi-Fi, go to the firmware (v2 something by default), and update to the latest (v3, which fixes everything).You need to run the PID calibration / (for the "stability" vibration compensation setting) after the update. **Slow. It. DOWN.**The printer has onboard vibration compensation (PID), but you have to turn it on after each print. (Start print, then set time to "stable.") It's lame and odd that this cannot be enabled by default, because it's sort of an essential feature ... prints will be somewhat slower than the official time in the gcode, but will look way nicer, and be less likely to fail.Also, the slicer settings are absurdly TURBO by default. I turned everything down in the machine limits part of the slicer, and cut all the values (velocity, jerk, acceleration) in half. I call this the "gentle" setting, for naming, and use this as my default printer setting.With stability and "gentle," the printer just feels nice and peaceful and chill while printing. I was having a hard time to get prints to complete, on the default "berserk" setting.It still sounds like a wind tunnel, though. The fans are annoying, and probably not necessary to be that loud. The printer itself (motors, etc.) is pretty quiet. **Get It Sliced Right**The default slicer is the AnyCubic slicer, which is a fork of the PrusaSlicer. The project files are identical, you can read and write them with either program.I actually like the AnyCubic slicer a little better, it looks nicer (and of course has the printer in there, by default.)I did need to tweak the settings. Some things that worked for me:* 3 perimeters, rather than 2, is much stronger and looks better* Gyroid at low density (10 - 20%) is a great infill. The curves make it strong, and it looks awesome (especially in clear)* Hilbert curves for surfaces look nice* No skirt or brim* I turn OFF "Detecting Bridging Perimeters" ... it causes more problems than it solves. For instance, if you have a small screw screw hole, it will close off the top "bridge" even if the hole would have printed just fine.* Stagger inner seams (for strength and printability), and set the outer seam to "rear" (looks best, of the options) **Upgradable Nozzle + Carbon Fiber**When the printer first came out, it took a few months for nozzles to appear, since anycubic reengineered their nozzles for the Kobra 2 series. You can get nice ones now, I upgraded to a ruby 0.6 mm nozzle from durozzle (available Amazon for 25 bucks).Ruby is 9 on the hardness scale, basically right behind diamond, which is 10.Ruby (or diamond) lets you print abrasive material, and I have discovered carbon-fiber embedded PLA. It's just a whole new world. Prints are strong, to do not warp or shrink, and feel and look nice.In addition to the hardened nozzle, to print CF you need to keep the filament in a dryer ... I have not figured out a placement that allows the filament to flow freely to the printer, without taking up massive space. (I just set the filament a few feet away, so no sharp bends.) But still, it's awesome and worth it, and I have no real plans to print anything else ...For the nozzle, I had to change only three settings:* nozzle diameter to 0.6 mm (duh)* linewidth to 0.67 mm* and layer to 0.3 mm.That was it, I kept the previous "gentle" speeds. **IT'S ALIVE**The printer is awesome. BUT Anycubic deserves minus one star, for sure, for shipping a broken printer (bad firmware). Printers are difficult enough, and although I eventually found the solution, I went down the rabbit hole of thinking it was overheating (?) or browning out (?).People ask this question on line (was very common on the Vyper), and many of the threads end in "it's still not working" ... why does AnyCubic not post the solution?(I have a friend with a Vyper, that stopped working in the same way ... I did not know about it when I got my printer. The hang issue is VERY COMMON, but somewhat sporadic, and really hard to debug.) **Conclusion**This printer took a LOT more effort to bring up than I was expecting. Along with the firmware issue, "stable" should be on by default.The default slicer settings are meant to sell the printer on SPEED, which is good because it means the printer is solid, but need to be slowed down to something reasonable, to actually have nice prints.BUT the end result is really cool, for $500 plus a little more for accessories (hardened nozzle, and filament dryer).At some point, I'll see if there is a way to make it less loud (the fans could at least be turned down), which is my one remaining gripe.Overall, solid, would recommend.

ترست بايلوت

منذ شهر

منذ يوم واحد